Introduction

Three phase induction motor is the most popular type a.c. motor. it is very commonly used for industrial drives. It cheap , robust, efficient and reliable.It has good speed regulation and high starting torque. It requires little maintenance. It has a reasonable over load capacity.

Three phase induction motor is the most popular type a.c. motor. it is very commonly used for industrial drives. It cheap , robust, efficient and reliable.It has good speed regulation and high starting torque. It requires little maintenance. It has a reasonable over load capacity.

Construction

A three Phase induction motor essentially consists of two part the Stator and the Rotor. Stator is the stationary part and rotor is the rotating part.

Stator :

- It

is built up of high-grade alloy steel lamination to reduce eddy current

losses.the lamination slotted on the inner periphery and are

insulated from each other.

- These

Laminations are supported in a stator frame of cast iron or fabrication

steel plate.the insulated conductor placed in these slots.

- the

stator conductors are connected to form a three phase winding.the winding

may be either star or delta.

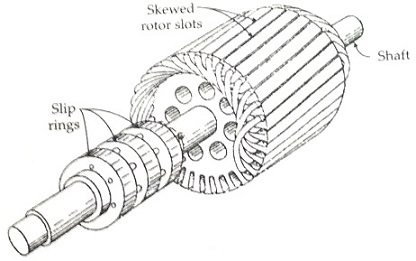

Rotor: The rotor is also built up of thin laminations of the same material as stator. the laminated cylindrical core is mounted directly on the shaft or spinder carried by the shaft.these laminations are slotted on their outer periphery to receive the rotor conductors. there are two types of induction motor rotors:

- Squirrel cage rotor or simply cage rotor

- Phase wound or wound rotor .Motors using this type of the rotor are also called slip ring motor.

Cage Rotor

Shape of Cage Rotor is cylindrical show in figure. Laminated core with slots nearly parallel to the shaft axis or skewed. Each slot contains uninsulated bar conductor of aluminium or copper.At each end of the rotor , the rotor bar conductors are short circuited by heavy end rings of the same material. A cage rotor is show in figure.

The skewing of cage rotor conductors offers the following advantages.

- More uniform torque is produce and noise is reduced during operation.

- The locking tendency of the rotor is reduced. During the locking , the rotor and stator teeth attract each other due to magnetic action.

The following advantages of the cage rotor are given below.

- The cage rotor is cheaper, and the construction is robust.

- The absence of the brushes reduces the risk of sparking.

- Its Maintenance is less.

- The power factor is higher

- The efficiency of the cage rotor is higher.

Wound Rotor or Slip Ring Rotor

The wound rotor consists of a slotted armature. Insulated conductor are put in the slots and connected to form a three phase double layer distributed winding similar to the stator winding. the rotor winding are connected in star.

1. To increases the starting torque and decreases the starting current from the supply

2. To control the speed of the motor.

The wound rotors have the following merits

1. High starting torque and low starting current.

2. Additional resistance can be connected in the rotor circuit to control the speed.

This comment has been removed by the author.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteI had read your blog, it was nice…! It was great experience for me…But,if you are looking for a high energy efficient electric motor, then contact our sales department at MM Engineering Services Ltd or visit our page.

ReplyDeleteI pay you really special thanks for sharing this informative content.

ReplyDelete3 Phase motor Cambodia

Hello Dear,

ReplyDeleteThank you for sharing beneficial blog. I read your blog about Induction motor Introduction and construction carefully. It is really brief introduction about 3 Phase Induction Motor. You describe the all over introduction, construction and define all the parts of Induction with a brief detail. MM Engineering Services Ltd

What is pole(2,4,6 & 8) in 3 phase motor . Please reply me

ReplyDeleteTo clean a venturi valve in a water softener, requires placing the water softener in service mode. This prevents water from entering the venturi while you disassemble it for cleaning.

ReplyDeleteprecise machining

If you are looking for threaded, brass, turned and stainless steel parts manufacturers, then Sanjay Precision is the best choice.

ReplyDeletePrecision Turned Components Parts

Brass Pin Manufacturers

Gear Blank Manufacturers

very intrsting topic. it clears my all doubt against three phase IM.

ReplyDeleteDo you like to cook different types of food? Or you would also like to work in a beautiful and attractive kitchen? If yes, then buy Induction Hob Singapore from EF. We look after our customers and have done so for nearly 40 years. We're a family owned business built on quality, honesty, and service.

ReplyDeletePost a Comment